Ultra Precision Molded Glass Optics

Ultra Precision Molded Glass Optics

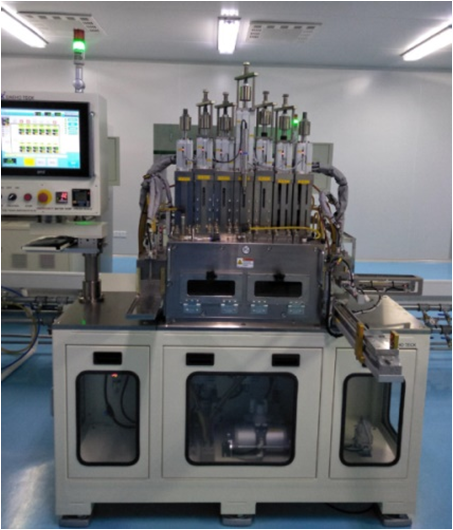

After years of dedicated R&D investment, Optowide has successfully overcome core challenges in aspheric technology. It has independently developed domestically leading High-precision Molded Glass Aspheric technology, which has been continuously advanced and upgraded into Ultra Precision Molded Glass technology platform. This technology comprehensively covers key links throughout the entire production process, including tungsten carbide alloy mold processing, integrated molding of aspheric tube caps, and manufacturing of products such as aspheric lens arrays, aspheric cylindrical lenses, and free-form surface lenses. It has established a full-process independent R&D system spanning mold design and manufacturing, glass molding, precision performance testing, and finished product coating.

Technical Precision at Advanced Industry Levels

Mold processing equipment achieves an accuracy of 2nm, with the surface form accuracy (RMS value) of tungsten steel molds reaching 10nm and that of molded products standing at 20nm. This lays a solid foundation for the stable mass production of high-precision optical products.

Core Product Portfolio

The product range includes 1.0mm-diameter micro glass-molded aspheric lenses, aspheric cylindrical lenses, aspheric lens arrays, square aspheric lenses, aspheric tube caps, free-form surface lenses, as well as prism units and prism arrays. With a processing size range from 0.5mm to 60mm, these products support integrated molding with metal brackets, effectively ensuring airtightness.

Team and Service Capabilities

Optowide has built a professional team proficient in mold design, product structural design, precision machining, and molding process development. Leveraging the company’s comprehensive optical supporting technology system, the team can efficiently respond to customers' needs for various glass aspheric products and boasts full-process delivery capabilities from product design and mass production to comprehensive testing.