Micro-nano Processing

Micro-nano Processing

Optowide has established a full-chain micro-nano optical components processing technology covering "design-manufacturing-precision processing-testing", which focused on the field of diffractive optics.

Comprehensive Diffractive Optics Technology Capabilities

Optowide has built a complete technologies matrix from underlying design to end-process manufacturing, and possesses customized design capabilities for complex Diffractive Optical Elements (DOEs). It can develop high-precision diffractive optical solutions to meet the needs of scenarios such as monochromatic beam splitting, spectral instrument adaptation, dispersion compensation, and high-energy laser beam combining.

1.1 Core Manufacturing Processes

Holographic Lithography: Supports an aperture size of 40×10mm, with a grating period ranging from 0.1 to 3000 line pairs per mm (lp/mm), which can meet the demand for mass production of high-precision gratings.

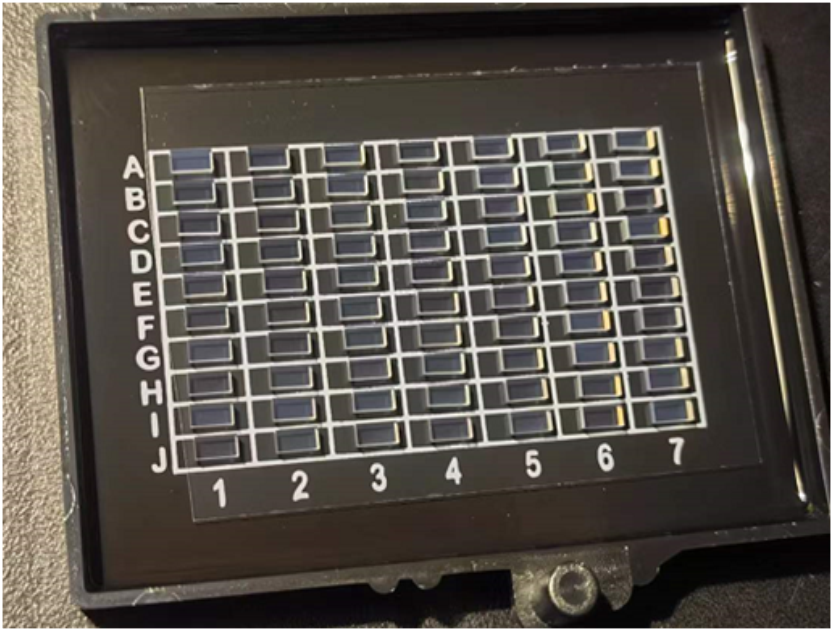

Laser Direct Writing: Focuses on the refined fabrication of DOEs, and satisfies high-precision scenario requirements such as micro-arrays and complex phase modulation.

Dry Etching: Enables high-precision etching of dielectric and metal materials, ensuring the structural stability and optical performance of micro-nano diffractive elements.

Nanoimprint Lithography: Maturely applied in the manufacturing of products such as gratings, optical waveguides, and polarizers, and adapts to the miniaturization and integration needs in fields like AR near-eye displays and consumer optics.

1.2 Multi-Material Compatibility

The aforementioned processes can be implemented on various substrates including dielectric oxides, silicon, fused silica, and polymers, flexibly meeting the special substrate requirements of different scenarios (e.g., the requirement for substrates with high temperature resistance and high damage threshold in high-energy laser scenarios).

Core Diffractive Optical Products and Applications

Volume Bragg Gratings (VBG): Relying on self-developed full-chain processing technology, Optowide has achieved mass production of VBG. As key components in the fields of fiber lasers and optical communications, VBG can be applied to scenarios such as laser mode-locking, narrowband filtering, high-power beam combining, and pulse shaping.

WSS Gratings: Developed to meet the needs of Wavelength Selective Switch (WSS) modules in the optical communication field, customized samples are available. These gratings support the construction of Reconfigurable Optical Add-Drop Multiplexer (ROADM) nodes in optical communication networks, improve the optical signal processing efficiency of nodes, and facilitate the evolution of high-speed optical communication systems toward larger bandwidth and higher flexibility.

Diffusers/DOEs: Customized samples are provided, which are widely used in scenarios such as laser homogenization, beam shaping, and 3D sensing.