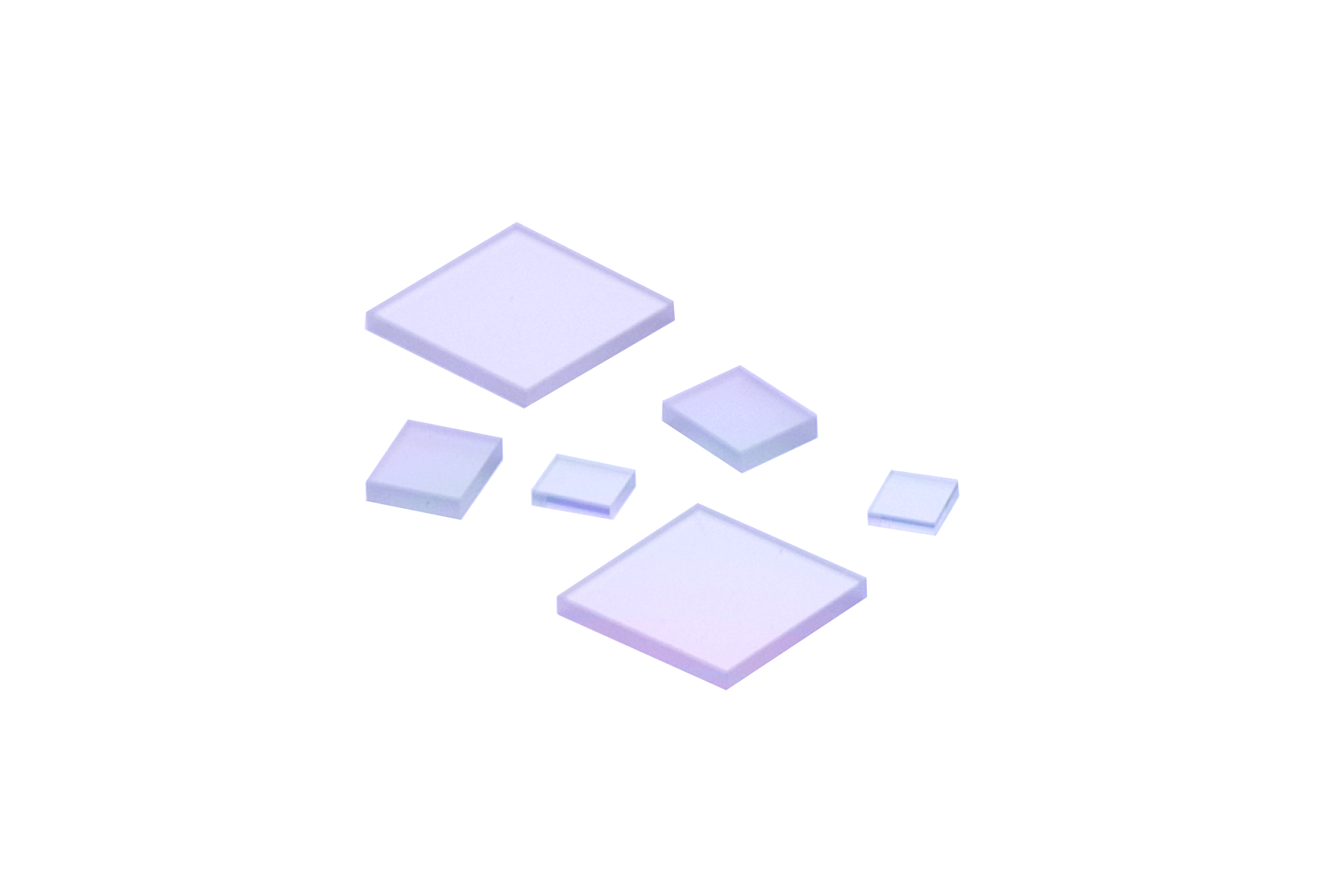

Mirrors

Mirrors are mainly used in scenarios such as beam steering, interferometry, imaging, and illumination. They use polished glass or metal as the substrate, and realize optical path control through specular reflection.

To improve reflection efficiency, the substrate surface is often coated with reflective films, which are mainly divided into two categories:

Metal Films

Common materials include aluminum, silver, gold, etc.

Metal films are soft and prone to scratches, usually requiring a protective coating. They are insensitive to incident angles, usable over a wide wavelength range, and meet the needs of most optical instruments.

Multilayer Dielectric Films

Suitable for scenarios requiring higher reflectivity, they can improve reflectivity and reduce absorption loss. Their reflection efficiency is affected by incident angle and wavelength, and the applicable incident angle (0° or 45°) and specific operating wavelength range are usually specified.

Technical Features & Advantages:

If you need more information on PRICE, TECHNICAL DETAILS or TAILOR SOLUTIONS, please contact us via sales@optowide.com or +86 (591) 3817 8298.